Developing a new bag and building a range can be so much fun but waiting 6-8 weeks for a sample is definitely not! Sample making and development can be a long process and you’re not guaranteed to receive the sample you thought you would. You could save weeks on your critical path by sending a cutting pattern to your supplier to make your sample so you don’t have any surprises when your sample does arrive.

So how can sending pattern pieces to your supplier help speed up the sampling process?

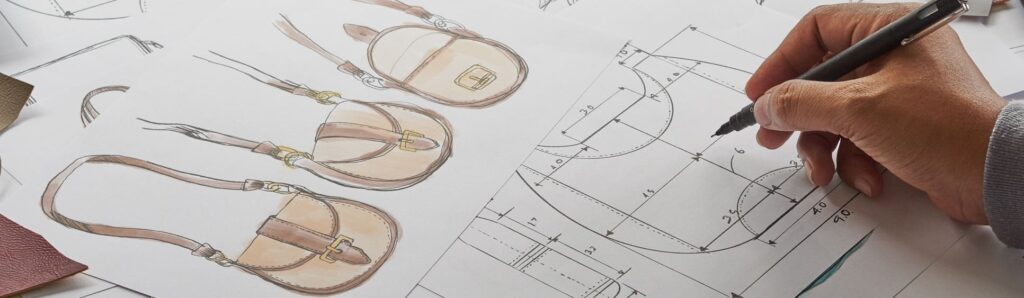

Sample rooms are often the busiest departments in a factory. Sample makers develop client’s designs to ensure production lines stay busy and factories remain profitable. Sample makers start developing a bag by studying a tech pack to understand the design and then go onto developing a pattern for the product. Very often, the first pattern is made by hand and on paper. The sample maker then makes a mock-up of the sample in a cheaper material to test the pattern and dimensions and then make a sample out of the materials you’ve requested. This process can take up to 8 weeks and then you’ll have to wait for shipping if your supplier is abroad. Once your sample arrives, you might find that the sample maker has accidentally missed a detail in the tech pack or overlooked a comment which can be frustrating. If your sample isn’t correct the first time, a second or third sample can incur major delays to your deadline and higher development costs.

Slow sample development can affect your critical path and delay your production which can cause bulk delivery delays and a stressful situation for you and your supplier.

As a trained and experienced pattern maker, I can help you save time and resources by creating a pattern for your bag. I speed up the development process by creating the pattern and sending you the first mock-up images so you can see exactly what you’ve requested. You can then send the pattern as a PDF to your supplier so all they have to do is cut and sew your sample. This process also gives your supplier extra piece of mind knowing that they don’t have to invest time and resources making multiple samples and they know they will be able to start production faster and more efficiently. If your supplier uses die-cutting to cut bulk production, a digital pattern will help speed up this process too because they will be supplied with the digital pattern pieces from the start.

So what do you get when you request a pattern for your design?

- You get peace-of-mind knowing your design will be made exactly as per the specification on your tech pack

- All the pattern pieces needed to sew your bag yourself or send to your supplier for sampling

- Instructions on how to make the bag according to the pattern

- A paper sample mock-up or sample in similar material so you can see the first mock-up before sending the pattern to your supplier

- A digital file with all pattern pieces labeled and ready for cutting

Why not speed up your sample process by requesting a pattern for your new development? We’d love to hear from you if you’re interested in requesting patterns. Please email us at info@oumacn.com for more information or purchase your next pattern from our online shop.